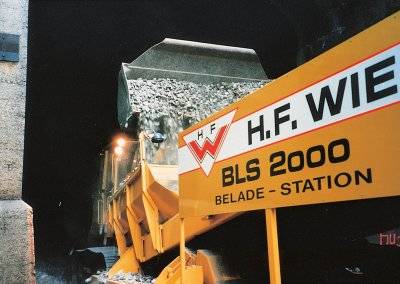

BLS-2000

A live wire

The loading station BLS-2000 allows materials to be loaded below live catenaries. Tooling only takes three minutes, which means that the BLS-2000 is operational as quickly as possible and is extremely practical in track construction projects thanks to the various combination options.

The BLS-2000 can also be used with MFS-38, MFS-40, MFS-100, BSW-2000, BSW-6000 and BSW-11000 and is therefore an all-rounder among the Wiebe group’s construction trains.

Total mass in tonnes

Axles

Kilometre/hour top speed

Lower, extend – and go!

The base of the pick-up belt and the transfer belt of the BLS-2000 is designed as a controllable conveyor with a conveyor width of 1920 millimetres. The loading station is tooled up after it reaches the construction site. This only takes 3 minutes. The receiving hopper is lowered to a height of maximum 1.15 metres above the SOK and the transfer belt is extended. After this work, the BLS-2000 is operational so that the BSW that is to be loaded is positioned in front of the BLS-2000 and the removed materials can be loaded into the BSW using the tracked loader, wheel loader and excavator via the loading station.

Technical data

| Type of machine | Loading station |

| Manufacturer | Plasser & Theurer |

| Registration year | 1990 |

| Total length over buffers | 12,87 m |

| Width | 3,05 m |

| Height | 3,95 m |

| Mass | 22 t |

| Axles | 2 |

| Smallest ridable track curve | 120 m |

| Permissible speed in train set | 100 km/h |

Your contact partner

Jakob Laukert

(Head of department track construction machines)

Would you like to contract us to carry out track construction work for you with this machine? Or would you like detailed information about our machine pool? Then just contact me!

The Wiebe group gas a broad-based machine pol that allows it to carry out a wide range of track construction projects, be it the construction of new tracks, or the modernisation, removal of maintenance of existing tracks. This ensures that we are equipped to take on any tasks using suitable machines or combinations of machines.

Other machines

MFS 40/4-A-ZW

The material wagon moves independently on tracks and ensures uninterrupted operation.

MFS 40/4-ZW-B

Automatic pre-selections allow smooth use of this material wagon with an integrated digger.

BSW-2000/6000/11000

This bunker bulk goods wagon can be used as a silo or conveyor wagon.

BLS-2000-R

This loading station can also load materials on track-free surfaces thanks to its crawler chassis.