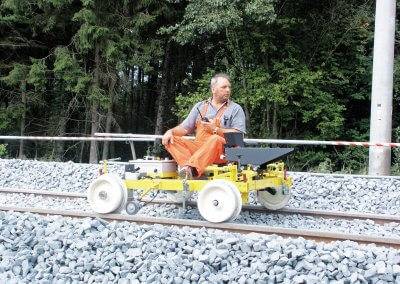

Tamping Express 09-3X

The sprinter

The large number of sleepers installed on ballast in track systems not only ensure a constant and even gauge width, they also bear the weight of the rails, which is a amazing feat considering they have a minimum deadweight of just 49 kilograms per metre.

But to be able to guarantee absolute safe when trains weighing many tonnes use the track, the focus is not just on the quality of the sleepers but also on the foundations. And this is achieved by stable and also elastic tamping below the sleepers – a task that the Tamping Express 09-3X completes quickly, thoroughly and flexibly.

Total mass in tonnes

Axles

Metres/hour maximum tamping output

Maximum output, minimum work effort

Track tamping is measured in terms of speed and uniformity, which is why the Tamping Express 09-3X can be used in a cyclic mode or in a single-sleeper or three-sleeper mode. This reduces the time required at the construction site. The same also applies to the radius: The Tamping Express can also process minimal track radii of just 190 metres.

Technical data

| Type of machine | Tamping machine |

| Manufacturer | Plasser & Theurer |

| Registration year | 2003 |

| Total length over buffers | 29,89 m | ||

| Width | 3,00 m | ||

| Height | 4,00 m | ||

| Mass | 94 t | ||

| Axles | 7 | ||

| Permissible speed in train set | 100 km/h | Run by itself | 100 km/h |

Motor

| Manufacturer | KHD |

| Type | BF 8M 10 15 C |

| Power | 440 kW |

Your contact partner

Frank Zarbock

(Head of department tamping machines)

The Tamping Express 09-3X lives up to its name: Thanks to its 3-sleeper tamping cycle, this machine can tamp 2 kilometres of track in just one hour – this definitely fall under the category of fast tamping.

And it does not compromise on quality either. The tamping aggregates work in parallel for optimum track tamping results near the sleepers. State-of-the-art technology ensures that the process is completed evenly and in accordance with the local track situation.

Other machines

WSM 08-275 3S

The tamping work below the switches is carried out with this switch tamping and alignment machine thanks to the 3-rail lift in compliance with the latest guidelines.

09-32 4SY

Thanks to a laser-supported 3-rail lift, even split sleepers can be processed by this very versatile track and switch tamping machine.

09-32 4S

In addition to conventional models, large B75 sleepers can also be tamped with this universal track and switch tamping machine.

WSM 08-275 3SY

High-performance tamping of switches for all kinds of sleeper – this is the task of the WSM 08-275 3SY.